September 7, 2025

Knowing the types of valves used in chilled water system design is essential for dependable cooling, energy efficiency, and simple maintenance if you oversee a commercial building or industrial facility in Ajman. Pumping energy can be decreased, delta-T can be stabilized, and equipment life can be increased with the proper isolation, control, and balancing valve combination.

Each type of valve is described in this guide along with its place in the hydronic circuit and how BestAir Services can help with valve installation, design, and lifecycle maintenance.

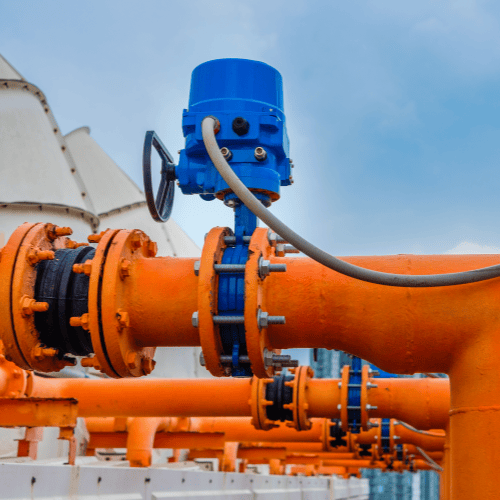

1) Isolation Valves (Gate & Butterfly)

Purpose: Shut off sections of the loop for service without draining the system.

- Gate valves offer low pressure drop when fully open; they’re suited to main headers and branches.

- Butterfly valves are compact, cost-effective, and common on larger diameters. With gear or lever actuators, they allow quick isolation in plant rooms and risers.

Where used: Main supply/return headers, equipment connections (chillers, pumps, AHUs), and floor isolation.

Butterfly valve

Gate Valve

Reference: General valve functions on Wikipedia—Valve

2) Globe Valves (Throttling & Control)

Purpose: Precise throttling due to the linear motion of the plug and seat.

Where used: Manual throttling or as the body for modulating control valves at AHU/FCU coils.

Why it matters: Globe valves maintain stable flow at partial openings, supporting accurate temperature control.

Learn about our coil optimization and controls work via HVAC services in Ajman

3) Check Valves (Non-Return)

Purpose: Prevent reverse flow that can cause pump short-cycling, unwanted mixing, or air entrainment.

Types: Swing, lift, and silent checks (the last reduces water hammer).

Where used: Pump discharges, parallel chiller arrangements, and bypasses.

Reference: Basic non-return principle on Wikipedia—Check valve

4) Strainers (Y-Type or Basket)

Purpose: Capture debris that would foul control valves, PICVs, and heat exchangers.

Placement: Upstream of pumps and control valves; incorporate blow-down ports for maintenance.

Tip: Dirty strainers are a common cause of coil under-performance—add them to your PM checklist.

5) Balancing Valves (Manual & Automatic)

Purpose: Ensure design flow to each coil/branch for proper heat transfer and stable delta-T.

- Manual balancing valves (with metering ports) allow commissioning teams to set flows using differential pressure readings.

- Automatic (pressure-independent) balancing valves maintain constant flow despite pressure fluctuations.

Result: Proper balancing cuts over-pumping and can improve overall chiller plant efficiency. ASHRAE highlights hydronic balancing as a core strategy for comfort and energy control; see ASHRAE—Standards & Guidelines

6) Control Valves (2-Way vs 3-Way)

Purpose: Regulate chilled water through coils to meet space loads.

- 2-Way control valves (with variable speed pumping) reduce flow as loads drop—lowering pump energy.

- 3-Way control valves maintain constant flow by bypassing water when the coil is satisfied—useful in legacy constant-volume systems.

2-Way

3-Way

Why 2-Way + VFDs? The U.S. DOE notes HVAC optimization and variable flow can cut pumping energy by 20–50% in suitable systems. See DOE O&M guidance: energy.gov

7) Pressure-Independent Control Valves (PICVs)

Purpose: Combine control + balancing in one body. A PICV delivers design flow at any valve position, independent of upstream pressure swings.

Benefits:

- Faster commissioning (flow set once on the PICV)

- Stable coil delta-T and tighter temperature control

- Less hunting and fewer BMS alarms

Where used: AHUs, FAHUs, and high-priority FCUs where precise control is vital (e.g., healthcare, data rooms, pharma)

8) Pressure Relief & Differential Pressure Control

Purpose: Protect equipment and maintain stable DP across circuits.

- Pressure relief valves (PRVs) protect against over-pressure events.

- Differential pressure control valves (DPCVs) hold a constant DP across terminal circuits, improving valve authority and control stability.

These are often specified alongside VFD pumps to avoid valve noise and coil overflow at part load.

9) Air Vents & Automatic Air Separators

Purpose: Remove entrained air that reduces heat transfer and causes noise/cavitation.

Where used: High points, near heat exchangers, and in dedicated air-separator assemblies on the primary loop.

Note: Trapped air can drop coil capacity significantly—routine venting is a low-cost performance win.

Reference: Air in hydronic systems overview on Wikipedia—Hydronics

10) Actuators & Controls (Thermal/Electric/Fail-Safe)

Valves are only as good as their actuators. Specify torque-appropriate, fail-safe actuators (spring-return) where power loss could threaten operations. Integrate with BMS for trend logs, alarms, and predictive maintenance.

Selection Tips of Type of Valves for Ajman’s Climate & Codes

- Dust & corrosion: Prefer epoxy-coated butterfly valves, stainless strainers, and sealed actuators for rooftop and coastal exposure.

- Energy performance: Favor 2-way control valves with VFDs, PICVs, and automatic balancing to reduce pump kW and improve comfort.

- Serviceability: Add isolation valves around coils, strainers with blow-downs, and union ends for rapid swap-outs.

- Compliance & commissioning: Follow manufacturer flow coefficients (Cv), respect valve authority (>0.5 ideal), and record setpoints during TAB.

Planning a retrofit? bestair handles valve installation in chilled water pipelines with shutdown-free methods (e.g., pipe freezing when applicable). Ask about our Ajman projects for more details.

Valve Locations in a Chilled Water Schematic for various type of valves

- Bypasses/header control: DPCVs or 3-way valves in constant-volume systems.

- Chiller connection: Isolation butterfly + check on discharge; strainers at evaporator inlet.

- Pump sets: Suction diffuser/strainer + discharge check + isolation.

- Branch take-offs: Isolation + balancing (manual or auto).

- Coils (AHU/FCU): Strainer → control valve (or PICV) → manual isolation on both sides → air vent at coil high point.

Maintenance Best Practices

- Quarterly: Clean strainers, verify actuator response, exercise isolation valves.

- Semi-annual: Re-check balancing setpoints and DP; inspect PICV cartridges; test relief valves.

- Annual: Review BMS trends for valve hunting, low delta-T, or persistent DP alarms—often signals of fouled strainers or mis-sized control valves.

Book a preventive visit with our commercial chiller service team

For most modern plants with VFD pumps, two-way valves are preferred to reduce flow at part load and save energy. Use three-way only when constant flow is required by legacy equipment.

PICVs eliminate branch-level balancing at coils, but you may still use manual balancing at main branches for systemwide control and documentation.

In dusty environments like Ajman, inspect quarterly (or more often during construction phases). Clogged strainers are a top cause of poor coil performance.

Verify coil flow (valve authority/PICV setting), clean strainers, and check DP across terminals. Many comfort issues trace back to flow imbalance.

Where feasible, yes. We assess options such as pipe freezing and staged isolation to minimize downtime. Start with a site survey

Mastering the types of valves used in chilled water system design helps you avoid hot/cold complaints, keep energy costs in check, and simplify maintenance. Whether you need PICV commissioning, isolation valve replacement, or full hydronic balancing, BestAir Services provides end-to-end support—from design review to installation and preventive care in Ajman and across the UAE.